E-CTFE (Halar®) coatings used as heavy-duty corrosion protection coating and chemical protection coating for your products and work pieces.

E-CTFE coating or Ethylene Chlorotrifluoroethylene is a Fluoropolymer coating and is analogous to the brand name Halar®, from the company Solvey. E-CTFE (Halar®) coatings are known for their usage as chemical protection coating from caustics, oxidizing agents and most solvents and as corrosion protection coating. Halar® coatings due to its properties are used in the chemical, filter, pump, medical and semi-conductor industries. Halar® coatings exhibit very good electrically insulating or antistatic properties, very good UV resistance for exterior use, is machinable and has a very high purity.

Halar® coatings are also available for contact with food, in line with the US FDA. For medical applications, Halar® medical Black is both electrically insulating and sterilizable.

Furthermore, E-CTFE (Halar®) coatings have a very good temperature resistance up to 150° and are nearly insensitive to common acids and alkalis

Halar® coatings can be applied in layer thicknesses from 300 to over 1000 µm.

E-CTFE (Halar®) as chemical protection coating

Due to their good resistance to acids and bases, E-CTFE (Halar®) coatings are very well suited as chemical protection coatings, wherever damage by chemicals is to be expected.

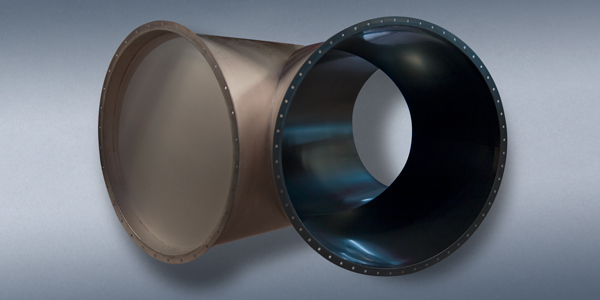

Some of the main applications of Halar® coatings are interior tank and pipe coatings, various containers, vessels or equipment, in short, wherever aggressive chemicals are used and there is a need for a chemical protection coating. Another advantage of E-CTFE (Halar®) as a chemical protection coating is its excellent non-stick properties, which can provide additional benefits for use in the above-mentioned industries.

E-CTFE (Halar®) as corrosion protection coating

Corrosion protection Coatings based on E-CTFE (Halar®) offer reliable protection for surfaces against corrosion. The lifetime of components in areas threatened by corrosion can thus be significantly extended.

Corrosion protection Coatings based on fluoroplastics such as E-CTFE (Halar®) have excellent thermoplastic properties and allow layer thicknesses of up to 2mm.

More about corrosion protection coatings.

E-CTFE (Halar®) is electrically insulating or with an anti-static version according to ATEX-2014-34-EU Guidelines.

The electrically conductive and electrically insulating properties of E-CTFE (Halar®) coatings make them suitable for use in potentially explosive atmospheres. Electrically insulating coatings with E-CTFE (Halar®) can achieve an electrical breakdown force of up to 35 kV / mm. The antistatic version of the Halar® coating can achieve a surface resistance of approximately 106 Ω to 106 Ω.

Halar® coatings comply with ATEX-2014-34-EU, for most electronic equipment.

Dieses Beschichtungsverfahren finden Sie bei uns bei folgenden Unternehmen:

![]() ADELHELM Kunststoffbeschichtungen GmbH

ADELHELM Kunststoffbeschichtungen GmbH

![]() EPOSINT AG Technische Kunststoffbeschichtungen

EPOSINT AG Technische Kunststoffbeschichtungen

![]() ADELHELM LubriCoat North America LLC

ADELHELM LubriCoat North America LLC